Tell Your Story….

7. Posted 01-10-18

My

time

at

Ditchburn’s

started

on

the

9th

May

1963,

and

finished

on

the

30th

July

1973,

but

the

intervening

years

were

fabulous.

In

my

younger

days

I

worked

on

radios,

but

that

was

before

I

started

working

so

I

was

well

adversed

in

Radio,

Audio

and

electrical

and

mechanical engineering you might say self taught, and i also went to night school to gain paper qualifications..

I

was

19

years

old

and

had

three

jobs

before

I

started

with

the

company.

I

started

on

the

Monday

morning

in

fear

and

trepidation

I

was

on

electrical

test

a

job

I

hated,

the

test

engineer

was

Tony

Toues

I

was

in

the

job

2

days

when

I

found

out

that

a

lad

called

Sutty

wanted

my

job

so

I

saw

Sutty

he

said

that

he

wanted

the

job

as

he

had

already

been

there

a

few

months.

I

saw

Tommy

Greaves

who

was

in

charge

of

the

vending

department,

and

said

that

Sutty

wanted

the

job

I

got,

could

we

please

swap.

So

on

the

third

day

Sutty

got what he wanted and I got what I wanted a job on electrical production.

In

1963

we

were

tight

for

space

the

electrical

test

was

at

the

end

near

the

stairs,

the

electrical

assembly

was

on

one

side

all

the

length

of

the

room

on

the

other

side

of

the

room

were

the

boiler

assembly

shop

an

odd

job

engineering

shop,

and

one

I

never

got

to

the bottom of it was run by Rose Webster there were also two offices on the stairs side..

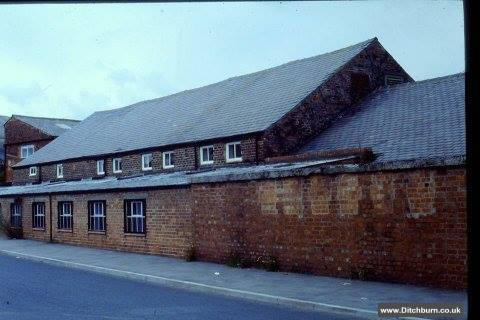

This

image

on

the

left

is

the

Dock

road

factory

and

shows

the

Factory Electrical department. circa 1949

The

blocked

out

windows

were

replaced

with

the

same

type

and

after

1956

the

area

formed

the

mechanism

department

for

the

Tonomat

machines

there

were

two

full

windows

in

the

middle

for

the

test

and

inspection

department

and

the

last

two

windows

were

the

Audio

department.

There

were

4

windows

in

the

six

that

were

taken

out.

Upstairs

were

the

production

office

of

Bill

Andrews,

and

later

other offices were included such as service office.

The

light

work

but

hectic

schedule

made

the

days

go

quick,

I

was

the

last

bench

just

before

the

harness

assembly

shop,

my

mate

next

door

was

Bob

Shaw

he

came

from

Blackpool

and

was

a

teddy

boy

at

heart.

The

days

were

full

of

mirth

and

we

employed

men

and

women,

I

think

there

were

four

women

and

three

men

in

the

department

,

but

soon

there

was

a

lad

started

and

I

made

room

for

him

and

he

was

next

to

the

harness

shop,

he

was

a

lad

I

knew

and

I

had

seen

him

grow

up

for

three

years

so

we

were

ok

and

the

jokes kept coming.

I

always

seem

to

get

the

job

of

making

harnesses

up

for

everyone

and

could

spend

two

days

on

making

each

one,

it

got

to

a

fine

art,

but

the

fact

was

that

we

were

all

supposed

to

make

our

own

harnesses

up.

There

was

a

works

social

club

called

the

“Domino

club”

it

organised

a

couple

of

outings

a

year

and

the

first

one

was

planned

for

July

and

another

one

in

December

and

I

went

on

both

of

them

and

they

were

good

do’s,

and

after

that

I

went

to

every

one

until

I

left.

In

1968,

I

took

over

the

club

as

chairman

in

later

years and remained in that position till I left the company in 1973.

There

was

talk

about

us

moving

to

the

other

side

of

Dock

Road,

we

at

that

time

were

employed

in

the

Dock

offices,

upstairs

was

electrical

boiler

manufacturing

section

for

the

hot

drink

vending

machines,

but

downstairs

was

the

machine

production

line

area,

this

area

was

the

full

length

of

the

building,

the

research

and

development

office

was

at

the

end

of

the

building

with

separate

locked

entrance. There was also a loading area entrance that the finished machines left the factory by.

In

May

1964

we

moved

lock

stock

and

barrel

to

the

new

factory

and

it

was

big,

you

could

fit

the

whole

of

production

into

it

and

had

acres

of

space

but

It

was

not

long

till

we

started

filling

it

up,

we

had

back

ground

music

section

in

there

that

took

up

minuscule

space

and

then

they

built

a

test

room

for

my

mate

Peter

Hamm,

but

before

he

got

the

job

I

was

assistant

to

Bill

the

test

engineer

for

a

few

weeks

in

another

part

of

the

factory,

I

worked

on

back

ground

music

(BGM)

for

a

few

months

mainly

sorting

out

the

poor

amplifiers.

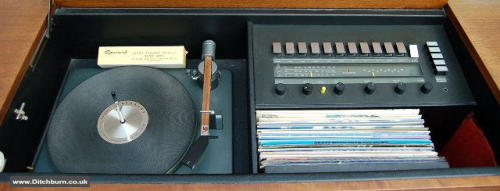

Shown

on

the

right

is

the

Ditchburn

Symphonette

BGM

system

and

tape,

this

provided

background

music

to

shops,

pubs,

and restaurants.

At

some

point

I

was

asked,

“not

told”

to

go

on

the

cigarette

machines

that

were

coming

in

from

Germany

and

spent

a

few

months

between

these

and

the

BGM

department.

There

were

two

of

these

type

of

machines

a

16

and

a

24

column

format,

they

would

hold

about

40

packets

of

cigarettes

per

stack

and

vended

change

which

was

set

by

changing

diodes,

if

the

diodes

went

open

or

short

circuit

as

happened

from

time

to

time

you

got

no

change,

if

all

the

diodes

went

faulty

I

found

out

they

would

not

vend

at

all,

see

more

about

this

below.

For

some

reason

we

had

a

110

volt

generator

run

from

a

three

phase

supply

to

test

the

first

machines

but we soon lost the generator.

So

by

now

I

was

sorting

cigarette

machines,

manufacturing

BGM

machines

still

working

on

vending

and

now

was

seconded

to

sort

out

problems

of

an

electrical

nature

on

vending

test

oh

and

I

worked

for

the

two

weeks

we

shut

down

for

holidays

so

went

off

and

was

chauffeur

driven

because

I

did

not

have

driving

licence,

so

they

took

me

to

Blackpool

to

sort

out

a

particular

problem

with

a

vending

machine

on

North

pier.

The

machine

a

v16

cigarette

vending

type

was

dead

but

the

power

was

ok,

I

checked

all

the

usual

points

for

voltage

and

everything

was

there

so

for

the

moment

I

was

stumped.

So

thinking

of

the

way

the

machine

worked

and

thinking

sideways

I

removed

one

column

of

diodes

placed

them

in

my

pocket

and

from

spares

box

put

in

a

set

of

diodes

on

column

1

and

it

vended

on

that

column

but

no

other

so

I

replaced

column

2

and

that

one

worked

and

continued

all

the

way

along

the

board

till

all

columns

worked.

I

then

realised

that

if

all

the

diodes

were

open

or

short

circuit

it

would

not

vend,

there

was

nothing

in

the

manual

about

this

situation.

I

asked

questions

of

the

owner

of

the

machine

had

anything

spectacular

happened

before

it

went

dead,

he

said

the

only

thing

on

Sunday

morning

about

9

the

lights

went

off

and

came

on

again.

Two

weeks

later

I

got

a

call

from

the

engineer

and

he

asked

about

it

I

gave

my

response

and

told

him

to

replace

all

the

change

diodes

check

each

column

and

see

me

with

the

diodes

when

he

came

back

to

Lytham.

We

sent

both

sets

of

diodes

off

to

Germany

to

check

their

condition

all

of

them

were

burned

to

a

cinder.

So

I

checked

with

Blackpool

tram

ways

and

asked

for

information

on

the

trams

that

were

running

on

those

days

and

times

we

got

the

answer

back

it

was

the

same

tram

both

times

and

as

there

is

no

connection

with

the

tram

cables

they

run

on

600

volt

dc

not

connected

directly

in

any

way

to

the

mains

it

remains

a

mystery

to

this

day.

Apparently

there

was

a

problem

with

the

coronation

trams,

they

would

do

all

sorts

of

things

to

nearby

equipment

and

they

had

to

remove

them

from

service.

The

back

ground

music

moved

again

this

time

we

were

in

the

big

dry

dock

but

the

dry

dock

was

filled

in

and

a

second

floor

was

built

and

a

cargo

lift

put

in,

you

were

not

supposed

to

use

the

lift

if

you

took

goods

up,

you

walked

up

the

stairs,

the

floor

was

finished

as

pure

concrete

and

I

requested

that

the

floor

was

sealed

because

I

was

having

problems

with

my

feet

eventually

the

floor

was

sealed

and

that

cured

the

problem.

By

this

time

a

new

symphonaire

was

introduced

called

the

symphonette,

the

pre

amps

were

built

in

house

on

vero-board

to

expedite

construction

because

no

boards

were

ready,

so

I

built

them

up..

hundreds

of

them

then

later

we

got

printed

circuit

boards

the

job

was

far

easier.

These

symphonettes

contained

a

small

package

mullard

2

watt

amplifier,

and

a

tape

preamp.

So

by

this

time

I

was

working

between

all

the

departments

of

vending,

symphonaire,

BGM

and

Clairtone

filling

in

wherever

I

was

needed.

At

the

end

of

this

building

was

the

research

and

development

department

which

was

always

securely

locked

and

no

one

gained

entry

unless

you

worked

in

there.

The

one

thing

I

have

only

just

realised

is

that

there

was

no

component

stores

at

the

vending

department,

but

somehow

stuff

got

ordered,

and

now

I

do

not

know

how

or

why,

but

we

never

ran

short

of

anything.

Well

at

the

end

of

1966

I

had

another

job,

I

was

considered

for

a

new

venture,

the

Clairtone

radiograms,

so

between

66

and

67

i

worked

between

all

of

them

but

time

was

running

out

for

Clairtone,

the

company

was

in

trouble

in

Canada

the

Canadian

government

had

invested

80

million

dollars

into

it

but

the

concept

was

not

right

the

company

went

bust

in

1968.

We

had

a

range

of

radio

grams

from

the

project

G

to

the

G2

and

we

had

small

ones

and

big

ones

some

just

radio

and

record

players

some

with

tape

recorders

and

they

were

up

to

800

each.

Clairtone

were

in

the

sheriff’s

office

next

door

to

vending

The

company

went

bankrupt

but

the share capital is nothing and in 2018 the company was still in existence but not trading.

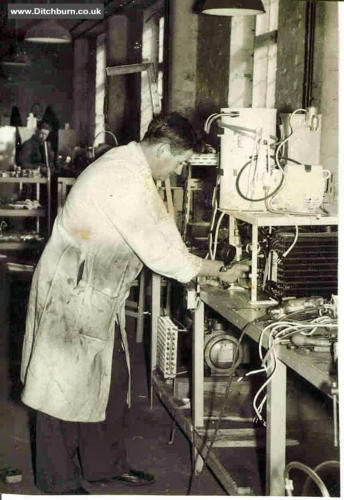

This

photo

shows

the

vending

division

in

circa

1960s,

downstairs

is

the

machine

production

track

and

upstairs

is

the

electrical

department

associated

with

production.

The

man

that

ran

the

vending

was

Tommy

Greaves,

and

electrical

test

was

Tony

Toose.

In

1964

when

we

vacated

the

unit

upstairs

was

the

pay

department

and

downstairs

was

an

ITC

1400

Computer

for

wages,

which

was

needed

as

by

that

time

we

had

600

or

more

staff

on

the

books at Ditchburn.

The

Ditchburn

Cold

Spa

Drinks

Vending

machine,

this

was

an

American

designed

machine

that

was

50%

US

and

50%

UK

manufactured,

this

was

to

circumvent

the

import

regulations

set

after

the

war,

the

Cold

Spa

was

for

cold

Drinks

and

there

was

also a Hot Spa Machine for Coffee and Tea

1968

was

a

momentous

year

I

thought,

I

had

finally

got

my

position

in

the

Ditchburn

Audio

Department,

and

strangely

it

was

in

May

of

that

year

I

was

given

three

months

to

make

my

mark

and

prove

my

worth,

or

I

was

out

of

the

department!…

I

did

it

in

one

month,

Bill

Andrews

was

the

boss

he

was

so

fierce,

everyone

feared

him

but

he

was

a

nice

kind

soul

and

secretly

he

was

soft

underneath,

he

helped

me

out

a

lot

in

my

time

with

Ditchburn

Equipment,

and

when

I

left

he

sent

a

letter

to

me

asking

me

to

come

back

on

the

following

Monday,

I

went

back

to

thank

him,

but

told

him

exactly

why

I

left

the

company

he

said

“You

are

a

star”

but

sadly

I

did

not

go back to work.

How

I

made

my

mark

on

audio

well

there

were

two

amplifiers

in

the

audio

department

both

small

Philips

amplifiers,

but

they

simply

did

not

work.

The

first

one

was

dead

on

sound

and

running

loads

of

HT

current,

most

of

the

voltages

were

ok,

but

the

output

stage

was

duff

but

drawing

current

for

fun,

so

I

investigated

the

output

and

realised

that

the

capacitors

in

the

unit

had

all

been

replaced

and

there

it

was…

a

so

simple

a

mistake,

the

–ve

bias

cap

had

been

put

in

the

wrong

way

round

shutting

off

the

bias,

I

replaced

the

capacitors

and

the

amplifier

was

now

working

great.

The

second

one

was

the

output

protector

it

was

a

dead

short,

after

repair,

it

was now ok. I had made my mark and got the job fixing two jobs that had hung around for at least four years.

The

audio

department

handled

a

number

of

amplifiers

from

juke

boxes

to

public

address

amplifiers

and

each

one

presented

a

different

problem.

There

was

the

ubiquitous

ones,

the

smaller

public

address

amplifiers

that

gave

the

most

trouble,

these

were

Philips

amplifiers

the

range

was

18

watt,

20

watt,

35

watt,

70

watt,

and

rather

special

400

watt,

we

just

had

two

of

these,

one

which

was

installed

at

a

company

on

the

A57

in

Manchester

it

was

a

massive

site

with

all

sorts

of

buildings

on

it,

and

they

made

sheds

and

garages,

there

were

7

amplifiers

on

this

site

alone

the

total

power

was

in

the

order

of

700

watts

or

so,

these

gave

little

trouble

but

wanted

a

5

year

service,

but

there

was

not

much

to

replace,

they

ran

4

x

807

Beam

Tetrode

Valves

in

the

output

stage,

which

were

completely

under

run

but

no

worries

the

only

things

you

had

to

do

was

check

and

set

the

bias

and

clean

the

safety

contacts,

this

was

a

system

of

controlling

the

amp

if

the

speakers

got

inadvertently

disconnected

(

a

relay

to

protect

the

output

transformer

)

and

adjust

the

gap

of

the

contacts

for

safe

operation.

We

also

had

a

few

25

watt

Reslo

amplifiers,

but

in

the

main

most

of

the

work

was

juke

box

related

.

To

test

these,

the

final

test

was

to

disconnect

the

speakers

turn

them

up

full

bore

and

watch

the

sparks

fly.

We

also

took

on

Eagle

amplifiers

it

was

a

try

out

the

TPA30

and

the

PA539

these

were

tried

and

found

to

be

good

enough

to

press

them

in

service

and

were

reasonably

cheap

at

least

cheaper

than

the

Philips

amplifiers

but

sadly

they

never

needed

service

I

suppose you could say that was good.

I

must

stop

using

the

term

“jukebox”

GND

(Geoffrey

Norman

Ditchburn

)

would

not

like

it,

he

only

called

them

by

their

correct

name

which

is

“Automatic

Phonographs”.

In

1968

towards

the

end

of

the

year

we

got

an

amplifier

for

evaluation

it

was

supposed

to

be

a

30

watt

solid

state

amplifier

of

superior

performance

so

I

was

given

the

task

of

writing

a

report,

all

went

well

till

I

got

to

the

final

output

test.

It

was

30

watt

the

first

amp

that

the

company

had

produced

in

the

solid

state

format,

there

was

plenty

of

HT

to

support

the

theory,

but

transistors

being

what

they

were

then

were

not

up

to

much

above

20

watts.

The

output

no

matter

how

I

measured

it

was

just

18

watts

RMS

into

a

4

ohm

load.

The

amplifier

did

not

make

it

to

our

inventory

and

the

company

shelved

it.

You

see

amplifiers

were

rated

as

RMS,

Music

power,

IAHF,

and

a

few

more

nondescript

outputs

so

if

it

was

stated

30

watt

RMS

it

should

be

because this was the standard by which all were measured.

I

had

left

vending

behind

but

the

same

applied

in

the

Equipment

department,

I

had

to

deal

with

calls

from

service

engineers

about

faults

with

sound

systems,

this

was

completely

unofficial

but

the

service

engineer

at

the

works

could

not

answer

all

the

questions

he

was

after

all

just

a

contact,

but

he

worked

hard

and

I

helped

him

out.

The

chief

service

engineer

was

Ronnie

Cole,

he

originated

from

Blackpool

but

the

main

man

was

Mike

(

not

sure

of

his

second

name

)

he

would

rush

in

at

5

minutes

to

clocking

off

time

wanting

an

amplifier

to

go

out

on

transport

to

somewhere,

and

we

would

not

have

one

in

stock,

so

“mugwump

me”

would

locate

an

amplifier

in

a

box

service

it

and

send

it

out

that

night

just

in

time,

then

I

had

problems

getting

out

of

the

factory

because

the

staff

entrance was locked. so I went out through the main entrance. I did this so many times I cannot count them, but that was me.

Well

the

years

came

and

went,

and

I

was

still

happy

with

my

lot,

the

Juke

boxes

went

on,

we

had

more

of

a

range

of

jukeboxes

to

deal

with,

some

actually

were

rubbish

but

we

soldiered

on

with

them,

if

you

consult

the

machine

directory

you

will

see

that

of

those

non

Ditchburn

machines

we

put

out,

plenty

of

them

there

was

the…

Bal-Ami’s,

the

Seeburgs,

the

Telematic,

German

Wurlitzer’s

and

the

American

ones

from

the

2600

to

the

last

one

the

3800

so

we

had

a

lot

of

amplifiers

to

deal

with,

we

all

have

favorites,

and

mine

was

the

Tonomat

from

Germany,

the

T31,

I

have

one

of

these

at

home,

30

watts

into

two

Goodmans

Audiom

61

speakers,

at

30

watts

of

raw

valve

power

you

can’t

beat

it.

But

some

others

preferred

the

transistor

amplifiers,

the

only

ones

of

these

I

liked

was

the

2900

and

the

3000.

We

also

had

the

full

range

of

German

Wurlitzer’s

from

the

Lyric

M

to

the

tape

machines,

we

also

had

the

Seeburg

1000

a

fully

functioning

BGM

(Back

Ground

Music)

this

machine

played

vinyl

instead

of

tapes

and

if

I

could

get

one

this

would be my machine.

Arthur’s Dream Machine

The Seeburg 1000 BGM

We

occasionally

had

the

early

Ditchburn

machines

in

for

service

the

MK4

(

AKA

MK2

Music

maker

or

Fridge

)

was

one

that

came

in

occasionally

and

I

had

the

joy

of

servicing

just

one

amplifier

it

ran

2

x

PX4

Valves

in

the

output

stage

to

give

15

watts,

these

valves

are

now

considered

to

be

some

of

the

best

ever

produced

and

command

extremely

high

prices

around

£400

each,

it

had

these

same

output

valves

since

new

according

to

the

service

record

and

had

only

been

back

for

service

once

in

its

life

it

was

manufactured

in

1950.

The

MK6

came

in

but

I

did

not

get

the

amplifier,

they

seemed

to

rate

the

old

boxes

different

to

the

new

ones

for

some

reason.

One

task

all

of

us

did

was

stock

taking

on

the

inventory

in

stock,

we

all

spent

one

day

every

year

doing

a

stock

check,

one

year

I

got

the

task

of

checking

the

old

stock,

it

was

the

parts

for

the

old

mk4

machines

(

MK2

Fridge

)

and

then

I

found

out

there

were

1000s

of

most

parts,

which

were

then

scrapped,

At

this

time

the

Bal

Ami’s

had

something

to

answer

for,

they

stopped

production

of

MK4

and

MK6

(

AKA

MK2

and

MK2R

)

machines,

The

Bal-AMI

played

40

records

and

both

sides,

but

the

Ditchburn

could

only

play

1

side,

Ditchburn

was

the

first

to

produce

machines

from

scratch

from

American

drawings,

but

sadly

they

were

all

owned by him and they were scrapped by him but there are exceptions still doing the rounds on sales sites.

We

got

taken

over

in

1970

by

BET

they

paid

2.3

million,

the

mood

did

not

change

and

GND

was

still

there

“but

the

mood

was

changing”

we

sold

out

the

vending

department

to

National

Vendors

UK

a

subsidiary

of

National

Vendors

inc

and

in

early

1971

for

about

1.3

million

we

put

in

a

bid

for

Gainesmead

but

they

returned

with

a

bid

for

us

and

in

October

1972.

We

sold

out

to

Gainesmead

for

2.3

million

when

we

sold

the

Juke

box

business

we

let

go

of

2800

Juke

boxes.

At

Christmas

we

were

hit

with

some

sad

news

my

very

good

friend

Mike

Town

had

been

out

for

some

shooting

with

his

son,

he

had

his

meal

and

went

to

the

car

to

collect

his

guns

to

clean

them,

mike

had

been

ill

for

a

couple

of

months

he

was

losing

his

sight

though

that

might

have

been

temporary.

He

reached

in

to

the

car

and

grabbed

the

gun

and

it

went

off

he

had

left

one

up

the

spout

and

not

broken

the

gun

why

I

do

not

know,

the

trigger

was

sensitive

and

shot

himself,

the

verdict

was

suicide

but

I

do

not

believe

that

for

one

minute

he

loved

his

wife

and

family,

he

would

not

put

them

through

this

on

purpose.

I

think

a

good

verdict

would

have

been

misadventure

and

to

my

mind

that

is

what

I

believe.

Mike

Town

was

the

sales

director

he

did

vending

mostly

but

did

work

for

the

equipment

side

as

well.

He

was

the

only

director

to

want

foreigners

doing

and

he

brought

loads

of

bits

in

from

his

children.

We

were

closed

till

2nd

January

so

I

did not know till then he was dead, RIP Mike.

I

decided

that

that

was

that

I

had

lost

the

one

man

that

meant

something

to

me

I

was

definitely

leaving

so

I

made

the

announcement,

I

told

the

company

I

was

having

that

day

of

the

funeral

off,

they

said

if

I

did

I

would

get

the

sack

so

I

just

said

sack

me!

The

whole

staff joined me at the funeral, the company had relented, the whole works closed for the day and we all packed the crematorium.

The

Company

was

now

called

Gainesmead

Automatics

from

the

previous

October

and

in

April

1973

we

came

back

to

work

after

the

weekend

to

find

the

audio

department

in

disarray

the

next

door

had

gone

and

it

was

one

big

department

it

was

horrible

we

had

a

jukebox

in

the

middle

of

the

room

the

Tonomat’s

were

cleared

away

and

in

their

place

there

was

200

selections

Seeburgs

and

NSM

juke boxes I now refer to the new shitty music the MSM it was, and four people were missing from the staff.

I

was

glad

when

the

end

of

July

came

I

left

but

had

one

more

duty

to

perform

I

was

the

chairman

of

the

Domino

club

and

my

last

engagement

was

to

take

them

to

the

Isle

of

Man

for

Bank

holiday

Monday,

we

arrived

by

sea

and

it

was

a

holiday

everything

was

shut,

and

even

worse

there

had

been

a

murder

on

the

Island

the

week

before,

we

went

for

lunch

went

on

a

tram

ride

down

the

prom,

looked at the burned out wreck of the leisure complex and went to a go cart rink then came home, it was a complete let down.

I

started

my

new

job

on

the

Tuesday

my

life

was

no

longer

the

same

I

had

lost

the

best

job

of

my

life

and

would

never

return

to

normality.

Finally

the

back

ground

music

division

was

eventually

sold

out

to

an

English

subsidiary

of

an

American

company

then

to

3M

for

1.2

million.

And

that

was

the

end

of

The

Ditchburn

Organisation.

We

sold

the

going

concern

to

BET

they

sold

the

lot

off

for

4.7

million

in

separate

lots

after

paying

us

2.3

million.

The

day

I

left

Ditchburn’s

the

staff

presented

me

with

a

tankard

but

unfortunately

it

had on it the wording of Gainesmead on it, it simply said “to Arthur Phillips from friends at Gainesmead.

These

friends

were:

Bill

Andrews,

Ronnie

Eastwood,

John

Hesketh,

Leslie

Dyson,

Peter

Cain,

Norman

Smith,

(Reg)

Reginald

Simpson,

Pete

Odea,

George

Lewis,

Rod

Tatersal,

and

loads

more

I

am

sorry

but

I

know

your

names

but

cannot

for

the

life

of

me

remember

them

I

have

always

had

a

problem

remembering

names

but

I

never

forget

your

face.

And

all

the

other

detail,

Peter

Cain

RIP

was

dead

before

I

left

Ditchburn’s.

I

was

promoted

to

head

audio

engineer

in

early

1969

after

Milton

King

left,

so

I

remain

chief

audio engineer at Ditchburn Equipment until i left.

Arthur Phillips

if

anyone

has

any

questions

for

Arthur

or

would

like

to

contact

him,

please

contact us via the button below and we will pass your details on to Arthur

To Be Continued ….

Photo Ref: DB187 Courtesy of Clive Mark

Photo Ref: DB098 Courtesy of Barry Cartmell

Photo Ref: DB097 Courtesy of Barry Cartmell

Photo Ref: DB227 Courtesy of EB

Photo Ref: DB229 Courtesy of EB

Photo ref: DB228 Courtesy of KD

Photo ref: DB230 Courtesy of KD

Below is the fantastically detailed story from Arthur Phillips in which he

discusses his time working at the Ditchburn Dock Road factory at Lytham.

The Photo on the right is of Tommy Greaves.

Tom

was

Arthur’s

first

boss,

he

was

in

charge

of

the

Vending

Department.

Tom,

a

qualified

engineer,

loved

his

work

hence

his

extended

service

to

the

company.

he

worked

for

Ditchburn for many years and retired when he was in his 70s

Photo Ref: DB231 Courtesy of Philip Marriott